Manufacturers of widest range of valves & fittings for all Applications

Manufacturers of widest range of valves & fittings for all Applications

Justifying its name in the market in terms of quality for the last six decades ‘LEADER’ stands éclat among valve manufacturers in India.

The company came into being when India was on threshold of industrial revolution and there was dearth of good valves manufacturers in India. It has over the years climbed its growth ladder successfully by keeping customer oriented approach.

We are proud to boast of our certifications from world-renowned organizations. The few are listed as under:

Our ferrous & non-ferrous foundries are certified as “ Well Known Foundry” under Indian Boiler Regulation 4c (2) of central boiler board, Govt. of India besides being PED certified by M/s. LRQA & AD2000 MERKBALT WO certified by TUV.

The company is nurtured by an efficient Board of Directors & highly

qualified professionals. They work as a team to achieve company goals.

Keeping in view the world market & to survive the global competition, ‘LEADER’ started with the LEADER EXPORTS. This step widened our areas of trading to U.K, U.A.E & major Gulf countries, Europe,South East Asia, U.S.A & to many more in international arena.

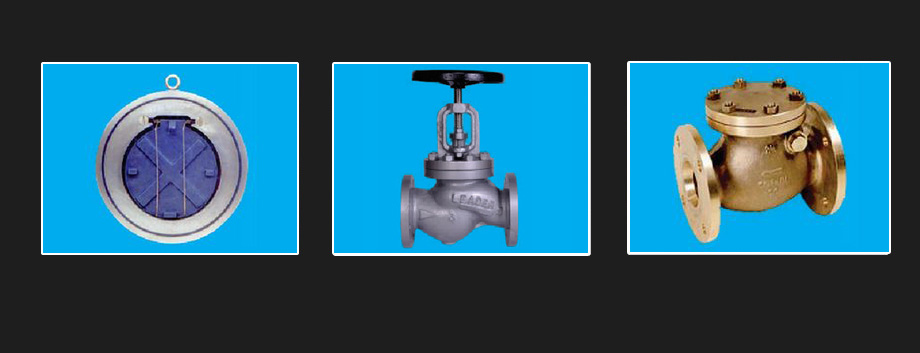

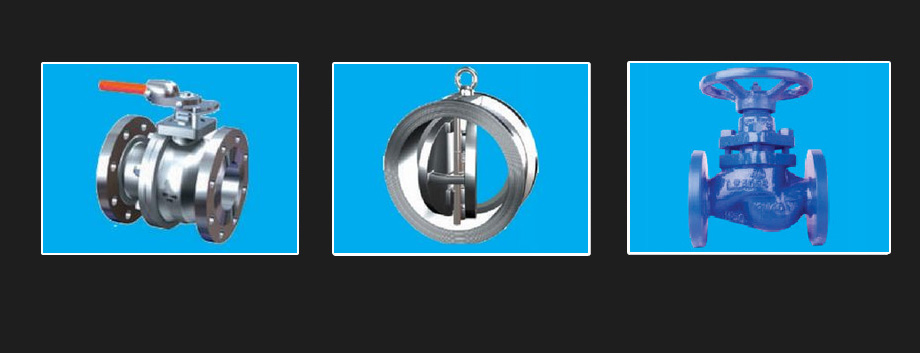

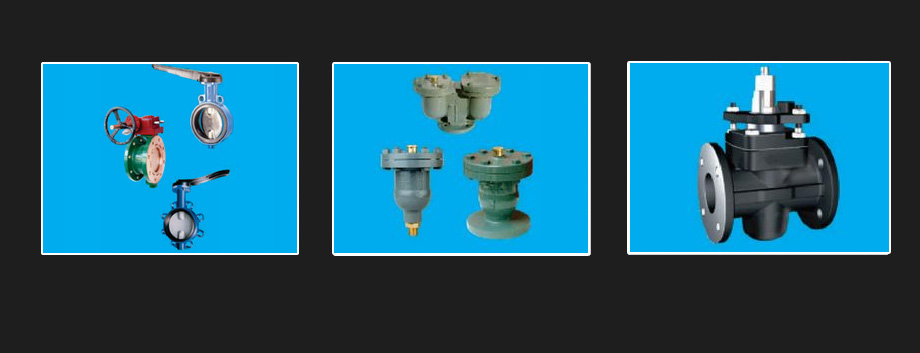

Leader offer complete range of valves for Domestic & Industrial applications Gate, Globe, Check, Ball, Butterfly, Plug, ARV, Float, Boiler Mountings, & High Pressure Forged Fittings ranging from Class-150 to Class-2500 , Size : 10mm to 1300mm, in all material grades CS, SS, AS,

Duplex ,CI, DI, D2, Bronze, GM, Brass, NAB, Monel, etc. We have in house design facility using sophisticated computer modeling software to develop special valves for critical applications. Please visit our web site www.leadervalves.com for details of our products.

With the booming manufacturing sector & wave of modernization touching India, our management & professionals are keeping pace with the growing international needs.

Foundry Our own foundries which are equipped with latest equipments and modern laboratories. Non-ferrous foundry is equipped with two Induction furnaces of twin crucible of 500 Kg. & 750 Kg capacity respectively. We can melt around 500 Tons copper alloy castings per month per shift basis. All our routine products in non-ferrous range are produced by shell moulding process. We also use Co2 and Green Sand moulds.

Copyright © 2012 Leader Valves Limited

By Tradexl Media (Google Adwords Certified Partner)